Process FMEA

Relyence

Nothing to download or install

Instant access, free web based trial

Process Reliability. Simplified.

Keep PFMEAs organised, aligned, and audit-ready with Relyence's always-in-sync technology.

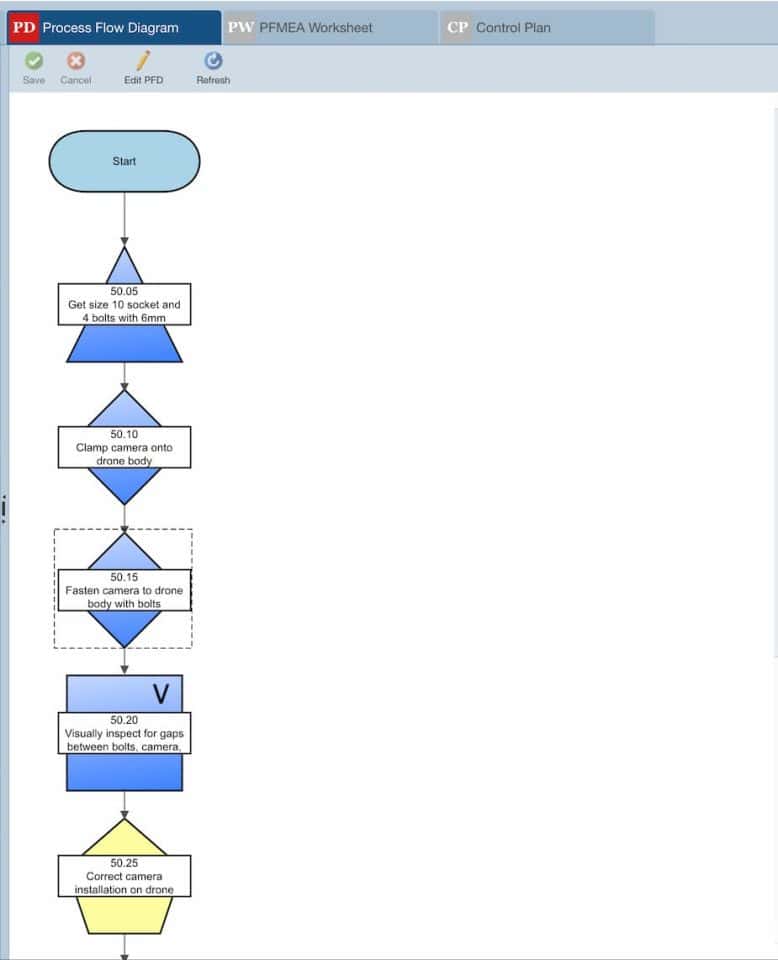

Streamline your process failure analyses with Relyence PFMEA software. Integrated with Process Flow Diagrams and Control Plans, it keeps everything aligned, collaborative, and audit-ready — from the initial draft to the finished analysis.

Relyence PFMEA software brings clarity and consistency to process failure mode and effects analysis. Designed to support a variety of standards, including the latest AIAG & VDA FMEA standard, it unifies PFMEAs with Process Flow Diagrams and Control Plans, aligning every stage of quality planning. With Knowledge Banks, SmartSuggest, Dashboards, Workflow Notifications, and Revisions, your team works faster while maintaining traceability and compliance. Whether migrating from spreadsheets or modernising your PFMEA tool, Relyence provides a web-based solution that scales across teams and industries

What our customers say...

“Relyence PFMEA has transformed how our team manages process risk. Always-in-sync integration and dashboards save us countless hours.”

Always-in-sync PFMEAs with PFDs and Control Plans — aligned, collaborative, and audit-ready.

Relyence PFMEA software enables process engineers to systematically identify, assess, and mitigate risks in manufacturing and service operations. Its unique, always-in-sync approach ensures that PFDs, PFMEA Worksheets, and Control Plans remain connected — changes in one automatically update the others. Built for collaboration, the platform features workflows, approvals, and notifications, while revisions and audit trails ensure every step remains transparent. Knowledge Banks and SmartSuggest accelerate data entry and promote consistency across projects. Combined with interactive dashboards and risk tracking, Relyence PFMEA provides teams with the clarity and confidence needed to enhance reliability and compliance across critical processes.

Relyence PFMEA key features

In addition to platform-wide capabilities, each Relyence module offers unique features developed for its specific analysis method. These specialist tools ensure engineers have the right functionality at the right time, helping achieve reliable, audit-ready results with less effort.

Relyence PFMEA offers users the following benefits...

Failure Direct Connect

Relyence Failure Direct Connect: Bridging FRACAS and FMEA for Continuous Improvement

Relyence Failure Direct Connect seamlessly integrates your DFMEAs, PFMEAs & FMECAs with your FRACAS data, providing valuable insights into the failure mechanism. By linking real-world failure data directly to your FMEA, Relyence closes the loop between your warranty returns and future design iterations.

One standout feature is the ability for users to suggest FMEA updates directly from FRACAS entries. This ensures that new issues are promptly incorporated into your FMEA, keeping your analysis current and comprehensive. The result? Enhanced collaboration, faster response times, and a powerful feedback loop that drives ongoing product reliability improvements.

PFMEA Control Plans

Relyence’s PFMEA Control Plan (CP) feature provides a structured approach to managing and documenting control strategies within your Process Failure Mode and Effects Analysis (PFMEA). It seamlessly integrates with other PFMEA components, including the Process Flow Diagram (PFD) and the PFMEA Worksheet, to ensure consistency and maintain data alignment across the analysis. This integration, enabled by Relyence’s “always-in-sync” technology, keeps process steps, characteristics, and control details up-to-date across the PFD, PFMEA Worksheet, and Control Plan, reducing risks of misalignment and audit issues.

The Control Plan starts with the process steps from the PFMEA and PFD, allowing users to document critical control parameters like control methods, specifications, sample sizes, and response actions if deviations occur. Any process characteristics entered in one part of the PFMEA will automatically appear in all relevant areas, enhancing efficiency and ensuring that control measures are comprehensively tracked. Users can further customise the CP layout to create specific views for team members, making it adaptable to various organisational needs and ensuring alignment with standards like AIAG & VDA and SAE.

Customisable Workflow & Approvals

Relyence FMEA and FRACAS empower you to take full control of your processes with customisable Workflows, Approvals, and Notifications. Designed to manage every step from start to finish, our intuitive Workflow Editor lets you tailor processes to your team structure and specific requirements. Configure everything with ease—from workflow steps and approval settings to automated notification messages and schedules.

Keep your team aligned and informed with a system that ensures seamless collaboration and accountability. Notifications prompt action at key stages, while approval mechanisms ensure compliance and precision. With Relyence, your workflows are as agile and efficient as your projects demand, giving you the flexibility to adapt and thrive in any industry.

Knowledge Banks

Control Your FMEAs with Relyence Knowledge Banks

Relyence Knowledge Banks streamline your FMEA process by providing a centralised repository for all your approved FMEA data, failure modes, effects, causes, and corrective actions. Engineers can search this data to quickly access proven solutions, saving time and ensuring consistency across projects.

The push feature allows you to effortlessly update your analyses with the latest information, keeping your analyses aligned and compliant. Plus, with built-in usage tracking, you gain visibility into how often and where your Knowledge Banks data is being applied, helping to identify best practices and areas for improvement. It’s a smarter, more efficient way to drive your risk analysis.

Relyence PFMEA Core Features

As part of the fully integrated Relyence platform, the PFMEA module benefits from a wide range of shared features. These cross-module capabilities allow engineers to save time, avoid duplication, and ensure analyses remain accurate and consistent across projects. Many of the features most valued by our customers are built-in here — visit the features section for the full breakdown.

Analysis Tree

The Analysis Tree, positioned between the Relyence Sidebar and main analysis area, provides a clear, hierarchical breakdown of your system, product, or process. While optional, it’s highly recommended for organising your analysis effectively.

As you select items in the Analysis Tree, the data displays the relevant filtered information, keeping your focus on the specific subsystem or section you’re working on. This intuitive filtering helps streamline data management across your Relyence modules, including FMEA, FRACAS, Reliability Prediction, RCM, and Maintainability Prediction.

Audit Trail

Relyence’s Audit Trail feature tracks all modifications to your data, including additions, edits, and deletions, along with who made the changes and when.

In the example shown, the Audit Trail for a Design FMEA shows detailed records of changes made to failure cause data—listing each update, who made it, previous values, and timestamps in descending order. For a comprehensive view, you can also export a full Audit Report, filtering by date and module for concise tracking.

Customisable Dashboards & Drill‑down Reporting

Relyence Dashboards provide a comprehensive, customisable overview of your product or system by gathering and organising key data. Users can create unlimited, personalised Dashboards based on set permissions.Using the Dashboard Editor, add widgets such as charts, tables, and graphs for high-level visual insights—many with drill-down features that lead directly to detailed analysis files, highlighting specific data for in-depth review.

Our PFMEA module shares data with the following Relyence products

Relyence PFMEA Integrations

RCM

Relyence RCM software helps you move from reactive fixes to proactive, data-driven maintenance strategies. With structured decision diagrams, analysing the outcomes of potential failure modes identified in Relyence FMEA. Seamlessly integrated with FMEA, Relyence RCM ensures your maintenance decisions are consistent, collaborative, and defensible—supporting reliability and safety across industries.

DFMEA

Relyence DFMEA streamlines and improves design risk analysis, providing structure, speed, and consistency. Fully web-based, it helps teams move beyond spreadsheets with built-in workflows and approvals, keeping your projects on track. Knowledge Banks promote the reuse of proven functions, failure modes, effects, causes, and recommended actions, whilst SmartSuggest provides intelligent recommendations, enabling quicker and easier creation and maintenance of high-quality analyses.

FRACAS

Relyence FRACAS software accelerates your reliability process with no-code customisations, allowing you to tailor failure reporting and corrective actions without IT support. It stands out by supporting industry standards such as 8D, DMAIC, and PDCA, as well as your own templates, and seamlessly connects with FMEA, Prediction, and Weibull tools to provide a single, unified reliability workflow.

FTA

Transform risk management with Relyence Fault Tree Analysis Software—your essential visual tool for reliability and safety. Build fault trees with a simple diagram editor, reuse events and trees through libraries, and migrate from Excel with ease. With built-in collaboration, reporting, and integrations to FMEA and FRACAS, Relyence FTA delivers a connected approach to managing reliability across your organisation.

Relyence PFMEA Overview

Relyence PFMEA software helps organisations move beyond spreadsheets and manual processes. It offers a powerful, browser-based platform for managing process risk. The software is fully aligned with various FMEA standards, including the latest AIAG & VDA FMEA methodologies. It brings together all the core elements of PFMEA — Process Flow Diagrams, Worksheets, and Control Plans — and keeps them automatically synchronised. This integration reduces duplication, errors, and rework, thereby improving efficiency and accuracy. It also provides engineers with a clear understanding of how process steps, failures, and control strategies are interconnected.

Knowledge Banks enable you to capture and reuse proven process steps, causes, and controls across various analyses. This ensures consistency and saves valuable time. SmartSuggest utilises previously entered high-level data to expedite setup and inform best practices. Built-in workflows, approvals, and notifications streamline collaboration across departments, facilitating seamless communication and efficient task management. Dashboards highlight risks and track actions to closure. Audit trails and revision history safeguard compliance, making it easier to meet industry requirements.

Relyence PFMEA is designed for global accessibility and supports cross-functional teams. It is used across many industries, including aerospace, automotive, electronics, medical devices, and rail. The software is scalable and secure. It seamlessly integrates with other Relyence modules such as DFMEA, FTA, and FRACAS. This creates a connected approach to reliability and risk management.

Relyence PFMEA Methodology

Process FMEA (PFMEA) is a structured method used to evaluate potential failures within a manufacturing or business process. The goal is to identify where and how a process might break down, assess the potential impact on quality or safety, and then implement controls to mitigate the risks.

The AIAG & VDA FMEA standard defines a step-by-step approach: mapping out the process, identifying failure modes, assigning severity, occurrence, and detection ratings, and developing action plans to address the highest risks. By capturing this information in a consistent format, PFMEAs provide a roadmap for prevention and continual improvement.

Relyence PFMEA software streamlines this methodology by keeping Process Flow Diagrams, PFMEAs, and Control Plans linked and updated in real-time. This ensures that all team members are working from the same information and that changes are reflected everywhere automatically. Combined with built-in collaboration tools and knowledge reuse, Relyence makes the PFMEA process more efficient, reliable, and easier to manage — freeing engineers to focus on improving outcomes rather than managing spreadsheets.

Relyence PFMEA... is it the right choice for you?

Next Steps

Register for our free, no obligation web based trial.

No credit/debit card required, nothing to download/install.

or book a Zoom/Teams demo to find out more.