Failure Mode Effects Analysis

Relyence

Nothing to download or install

Instant access, free web based trial

Smarter FMEA for Modern Engineering

Relyence FMEA Software

Streamline DFMEA, PFMEA, FMEA-MSR, and FMECA in one intuitive, web-based platform. Relyence FMEA keeps your analyses connected, collaborative, and compliant with various FMEA standards like AIAG & VDA.

Relyence FMEA software is designed to make failure mode and effects analysis simple, structured, and effective.

Whether you’re working on design FMEAs, process FMEAs, or monitoring safety risks, Relyence helps you stay in control. With built-in support for AIAG & VDA guidelines, always-in-sync links to Control Plans and Process Flow Diagrams, and features like Knowledge Banks and SmartSuggest, it saves time while ensuring consistency.

Fully web-based, Relyence enables engineers across teams and sites to work together seamlessly, with workflows, approvals, and notifications built in.

What our customers say...

The Knowledge Bank incorporated within the software has drastically cut the time it takes to create our shell PFMEA’s. If its D&PFMEA’s you need to create, this is the software that you need - Phillip H, Nasmyth Group

Your complete FMEA tool for design, process, and safety risk analysis.

Relyence FMEA brings together everything you need to perform efficient, consistent, and standards-compliant Failure Mode and Effects Analyses. Built for design and process engineers, it supports DFMEA, PFMEA, FMECA, and FMEA-MSR in line with AIAG & VDA as well as other international standards.

The unique Always-in-Sync capability keeps FMEAs aligned with Process Flow Diagrams and Control Plans, reducing duplication and preventing errors. Knowledge Banks and SmartSuggest accelerate analysis and drive consistency across teams and projects.

With integrated dashboards, access controls, audit trails, and revision control, Relyence makes collaboration seamless and secure — whether in aerospace, automotive, electronics, medical devices, or rail.

Multiple FMEA types supported

DFMEA

Our DFMEA software empowers engineers to identify and address design risks early on using standards-based methods, real-time collaboration, and built-in knowledge reuse, thereby preventing failures and enhancing product reliability across various industries.

PFMEA

Streamline your process failure analyses with Relyence PFMEA software. Integrated with Process Flow Diagrams and Control Plans, it keeps everything aligned, collaborative, and audit-ready — from the initial draft to the finished analysis.

FMEA-MSR

Streamline FMEA Monitoring and System Response (FMEA-MSR) analysis with Relyence FMEA-MSR software. Built to AIAG & VDA standards, it enhances reliability, supports collaboration, and maintains control over your safety-critical systems.

FMECA

Streamline your Failure Mode, Effects, and Criticality Analysis (FMECA) with Relyence FMECA software, uniquely designed for fast MIL-STD-1629A compliance, automated risk prioritisation, real-time team collaboration, and customisable analysis for aerospace, automotive, medical, and other industries. Get started today and see how Relyence can elevate your FMECA process.

Relyence FMEA key features

In addition to platform-wide capabilities, each Relyence module offers unique features developed for its specific analysis method. These specialist tools ensure engineers have the right functionality at the right time, helping achieve reliable, audit-ready results with less effort.

Relyence FMEA offers users the following benefits...

Knowledge Banks

Control Your FMEAs with Relyence Knowledge Banks

Relyence Knowledge Banks streamline your FMEA process by providing a centralised repository for all your approved FMEA data, failure modes, effects, causes, and corrective actions. Engineers can search this data to quickly access proven solutions, saving time and ensuring consistency across projects.

The push feature allows you to effortlessly update your analyses with the latest information, keeping your analyses aligned and compliant. Plus, with built-in usage tracking, you gain visibility into how often and where your Knowledge Banks data is being applied, helping to identify best practices and areas for improvement. It’s a smarter, more efficient way to drive your risk analysis.

Relyence FMEA SmartSuggest

The Relyence SmartSuggest feature allows users to select from relevant data previously populated, i.e.,

- SmartSuggest automates the process by which failure causes at higher levels are identified as Failure Modes at the next lower level. It connects the lower-level Failure Mode to its related higher-level Cause. The Severity of the lower-level Mode is automatically set to match the Severity of the parent Failure Mode associated with the higher-level Cause.

- Automate failure Modes at higher levels, becoming Effects at the next lower level. The lower-level Failure Effect is then connected to the higher-level Failure Mode. The Effect Severity for the lower-level Effect is automatically set to the maximum value from the Failure Mode Severity from the higher-level Failure Mode and any associated Failure Effects.

Customisable Workflow & Approvals

Relyence FMEA and FRACAS empower you to take full control of your processes with customisable Workflows, Approvals, and Notifications. Designed to manage every step from start to finish, our intuitive Workflow Editor lets you tailor processes to your team structure and specific requirements. Configure everything with ease—from workflow steps and approval settings to automated notification messages and schedules.

Keep your team aligned and informed with a system that ensures seamless collaboration and accountability. Notifications prompt action at key stages, while approval mechanisms ensure compliance and precision. With Relyence, your workflows are as agile and efficient as your projects demand, giving you the flexibility to adapt and thrive in any industry.

Failure Direct Connect

Relyence Failure Direct Connect: Bridging FRACAS and FMEA for Continuous Improvement

Relyence Failure Direct Connect seamlessly integrates your DFMEAs, PFMEAs & FMECAs with your FRACAS data, providing valuable insights into the failure mechanism. By linking real-world failure data directly to your FMEA, Relyence closes the loop between your warranty returns and future design iterations.

One standout feature is the ability for users to suggest FMEA updates directly from FRACAS entries. This ensures that new issues are promptly incorporated into your FMEA, keeping your analysis current and comprehensive. The result? Enhanced collaboration, faster response times, and a powerful feedback loop that drives ongoing product reliability improvements.

Custom Failure Mode Libraries

Custom FMEA Mode Library: Standardised, Efficient, and Tailored for Your Needs

The Custom FMEA Mode Library introduces a powerful way to streamline your piece-part DFMEA and FMECA processes. By creating a centralised repository of predefined failure modes and associated percentages for each part type, this feature ensures standardisation and consistency across your entire organisation.

Engineers no longer need to start from scratch for every analysis. Instead, they can leverage a comprehensive, predefined set of failure modes, accelerating the FMECA process and reducing the risk of missing critical issues.

The integration with Relyence Reliability Prediction also allows for a quick startup, pulling in relevant data when importing a Bill of Materials (BOM).

Relyence FMEA Core Features

As part of the fully integrated Relyence platform, the FMEA module benefits from a wide range of shared features. These cross-module capabilities allow engineers to save time, avoid duplication, and ensure analyses remain accurate and consistent across projects. Many of the features most valued by our customers are built-in here — visit the features section for the full breakdown.

Audit Trail

Relyence’s Audit Trail feature tracks all modifications to your data, including additions, edits, and deletions, along with who made the changes and when.

In the example shown, the Audit Trail for a Design FMEA shows detailed records of changes made to failure cause data—listing each update, who made it, previous values, and timestamps in descending order. For a comprehensive view, you can also export a full Audit Report, filtering by date and module for concise tracking.

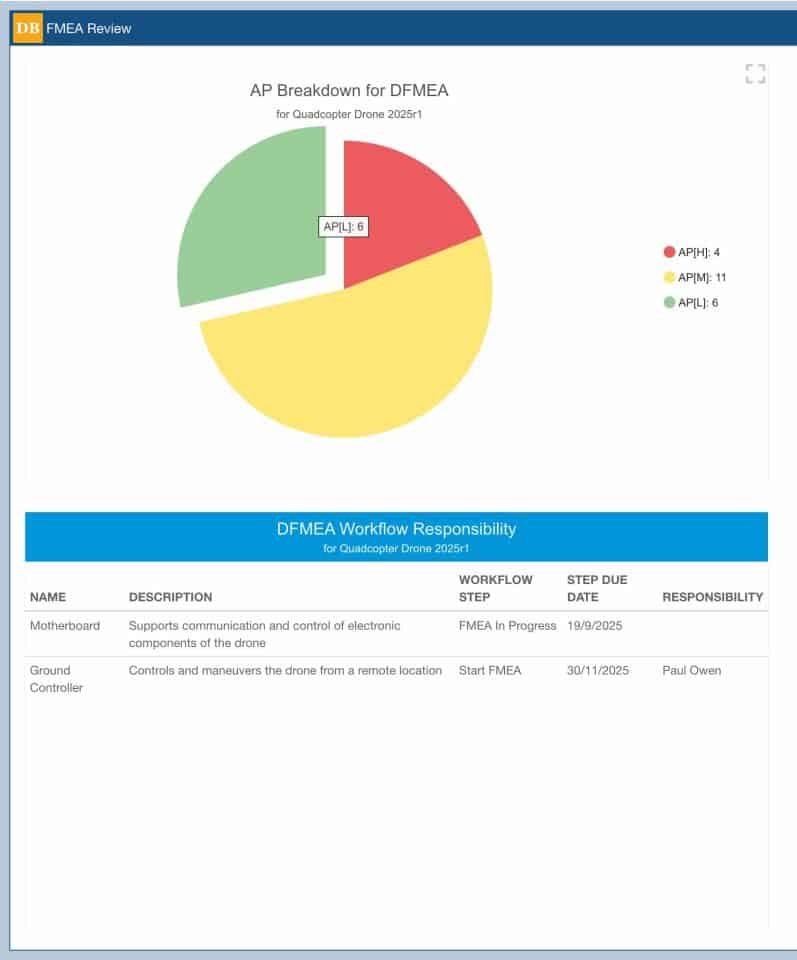

Customisable Dashboards & Drill‑down Reporting

Relyence Dashboards provide a comprehensive, customisable overview of your product or system by gathering and organising key data. Users can create unlimited, personalised Dashboards based on set permissions.Using the Dashboard Editor, add widgets such as charts, tables, and graphs for high-level visual insights—many with drill-down features that lead directly to detailed analysis files, highlighting specific data for in-depth review.

Analysis Tree

The Analysis Tree, positioned between the Relyence Sidebar and main analysis area, provides a clear, hierarchical breakdown of your system, product, or process. While optional, it’s highly recommended for organising your analysis effectively.

As you select items in the Analysis Tree, the data displays the relevant filtered information, keeping your focus on the specific subsystem or section you’re working on. This intuitive filtering helps streamline data management across your Relyence modules, including FMEA, FRACAS, Reliability Prediction, RCM, and Maintainability Prediction.

Our FMEA module shares data with the following Relyence products

Relyence FMEA Integrations

FRACAS

Relyence FRACAS software accelerates your reliability process with no-code customisations, allowing you to tailor failure reporting and corrective actions without IT support. It stands out by supporting industry standards such as 8D, DMAIC, and PDCA, as well as your own templates, and seamlessly connects with FMEA, Prediction, and Weibull tools to provide a single, unified reliability workflow.

FTA

Transform risk management with Relyence Fault Tree Analysis Software—your essential visual tool for reliability and safety. Build fault trees with a simple diagram editor, reuse events and trees through libraries, and migrate from Excel with ease. With built-in collaboration, reporting, and integrations to FMEA and FRACAS, Relyence FTA delivers a connected approach to managing reliability across your organisation.

Reliability Prediction

Relyence Reliability Prediction software makes it simple to calculate MTBF, model component reliability, and meet industry standards. With built-in part libraries, stress-based calculations, and integration across FMEAs, FRACAS, RBD, and Weibull, it turns raw data into actionable insights. Fully web-based, it’s designed for teams who need speed, accuracy, and collaboration in reliability analysis.

Relyence FMEA Overview

Engineered for today’s fast-paced engineering environments, Relyence FMEA software empowers your teams to achieve unparalleled efficiency and accuracy in FMEA management. The intuitive, browser-based platform not only supports all major methodologies — Design FMEA (DFMEA), Process FMEA (PFMEA), and Monitoring and System Response (FMEA-MSR) — but also guarantees full compliance with standards such as the AIAG & VDA.

PFMEs seamlessly link to Process Flow Diagrams and Control Plans. Relyence elevates your analysis workflow to ensure consistency, maximise productivity, and keep your insights continuously up-to-date.

Leverage Knowledge Banks to rapidly build and reuse powerful libraries of functions, failure modes, effects, causes, and recommended actions—driving project excellence while embedding proven best practices into every analysis. With SmartSuggest, you can propel your team’s productivity by linking to relevant entries from previous work. Together with robust collaboration features like workflows, approvals, notifications, and secure user/group permissions, Relyence guarantees your team is equipped for seamless and efficient teamwork.

Take command of compliance and oversight with comprehensive Audit Trails, Revision management, and configurable reporting dashboards designed to simplify governance. The browser-based design empowers engineers to achieve results from anywhere, at any time, eliminating IT constraints—from initial design reviews to dynamic shop-floor quality checks. By integrating effortlessly with FRACAS, Reliability Prediction, and Fault Tree Analysis tools, Relyence unifies and amplifies your entire risk and reliability process for maximum impact.

A selection of Relyence Failure Mode Effects Analysis (FMEA) software customers

Relyence FMEA Methodology

Failure Mode and Effects Analysis (FMEA) is a structured method for identifying potential problems before they occur. By examining how a product or process could fail, why it might fail, and what the effects would be, engineers can plan effective prevention and detection controls.

There are different types of FMEA depending on the context. DFMEA (Design FMEA) examines risks during the product design phase. PFMEA (Process FMEA) evaluates risks in manufacturing or service processes. FMEA-MSR (Monitoring and System Response) considers how systems behave in operation and how failures are detected or managed.

The AIAG & VDA Handbook provides a harmonised approach for conducting FMEAs, ensuring consistency across industries. Relyence FMEA is built to align with multiple standards while simplifying the process. Its linked diagrams, reusable knowledge libraries, and automation features eliminate repetitive admin tasks, allowing engineers to focus on engineering judgment.

Relyence FMEA... is it the right choice for you?

Next Steps

Register for our free, no obligation web based trial.

No credit/debit card required, nothing to download/install.

or book a Zoom/Teams demo to find out more.