This Dad says… “Absolutely!” Let’s find out why.

Failure Mode and Effects Analysis (FMEA) has been a staple of engineering best practice for over 85 years. It’s a structured methodology that helps engineers identify how things might fail, understand the consequences, and pinpoint the root causes. The goal? To reduce the likelihood of failure and increase the chances of spotting issues before they happen.

A well-executed Design FMEA becomes a living document—supporting safer designs, boosting reliability, and helping prevent the same issues from creeping back in later. It’s no wonder FMEAs are a standard requirement across many industries, especially automotive.

But what about motorsport? Why is Dad so convinced?

Let’s start with the obvious: motorsport is inherently risky. When your 17-year-old son is out there racing at circuits across the UK, nerves are par for the course. But when you’re also the one responsible for preparing, maintaining, and fixing the bike, the pressure ramps up.

Cue the sleepless nights: Did I torque that bolt? Did I grease that spindle?

Our race bike, a Yamaha R6, began life as a perfectly civilised road-going machine, built for the daily commute, Sunday blasts, and the occasional pillion ride. And you can be sure Yamaha’s engineers did their fair share of risk assessments to ensure it was roadworthy.

But the race track is a different beast. That same R6, now transformed into a full-blown race bike, spends its life screaming between 11,000 and 16,000 RPM, hitting top speed as often as the rider dares, and braking harder than the average road rider ever would. You’re now operating well outside the original design specification.

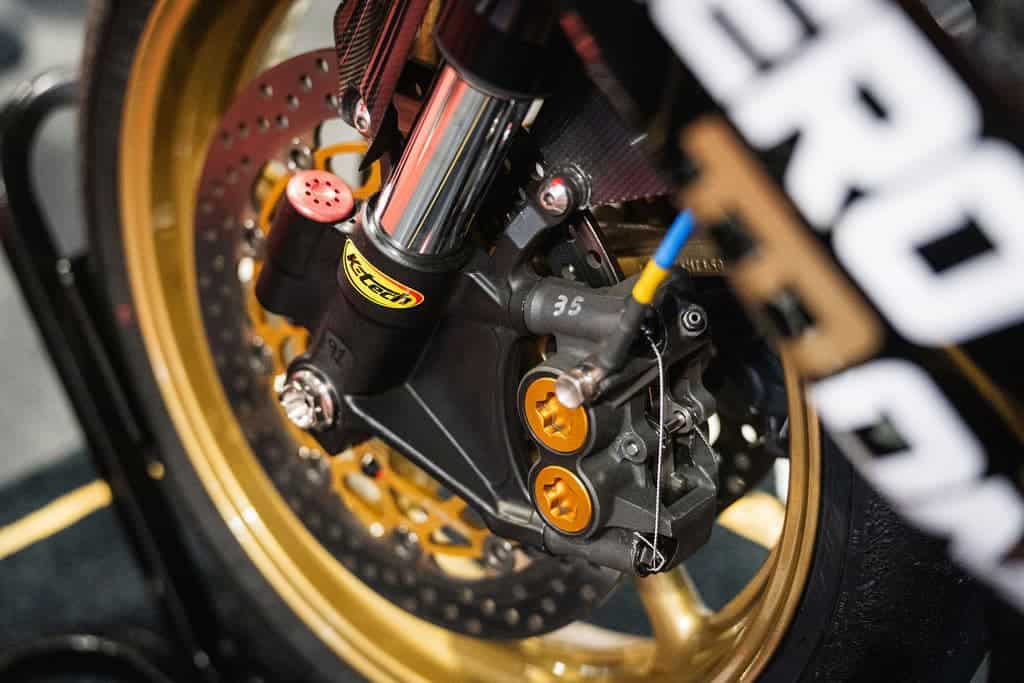

And when you’re repeatedly braking from over 160 mph for a tight hairpin, there’s no room for error. The front brake—comprising a single front wheel, twin discs, and a pair of callipers—does most, if not all, of the work. And yes, even in top-tier racing, callipers have been known to fall off. So you’ll understand why “Dad” (AKA pit crew and lead mechanic) takes a very particular interest in making sure things don’t shake loose.

Enter the humble FMEA

Let’s take a closer look at the R6’s front brakes. Each calliper is secured with two bolts. Inside the calliper, two pads are held by a single pin, which is locked in place with two R-clips. What could go wrong?

Here’s an extract from Dad’s “simple” FMEA on the Brake Calliper

Here’s how FMEA helps:

Lock wiring the calliper bolts together in a clockwise direction acts as a Prevention Control. If one bolt starts to turn anti-clockwise (i.e., loosen), it would have to tighten the opposing bolt—brilliant in its simplicity. It’s like having each bolt guard the other from working itself free.

Lock wire also serves as a Detection Control. In Dad’s workflow, the lock wire only goes on after the bolts are torqued to 35Nm. So if the wire’s in place, it’s a clear visual indicator the job’s been done right. And the bolts can’t be removed without cutting it.

Another simple but effective example? Dad’s “little red check marks”.

Why bother?

Because gear selector rods can and do fall off. Footpegs vibrate loose. And while threadlock has its place, it’s not always the solution—especially not when you’re constantly removing and refitting parts. (And rounding off bolt heads trackside is nobody’s idea of a good time.)

The red check marks are a quick, reliable Detection Control. Between sessions, Dad can glance over the bike. If the red dots still intact, nothing’s moved. If they’re broken, something’s come loose. Simple, visual, effective.

The result? Dad gets to sleep a bit better at night. And between sessions, instead of triple-checking bolts, he can focus on tyre temperatures, pressures, suspension settings, fuel levels, and the thousand other things a race bike demands.

Peace of mind, thanks to a bit of FMEA logic.

Maybe the question should be… Is there an industry or application where FMEA doesn’t have a place?

A Word of Thanks

Relyence would like to thank Zero To One Racing for letting us share this unique and very real-world FMEA application. It’s a refreshing departure from the highly regulated, NDA-covered environments we usually work in and a perfect example of how powerful FMEA can be, even at grassroots level.

So cheers to Evan, Dad, and the whole team. We’ll be watching closely and following your story as it unfolds.

Interested in how FMEA could help you?

Visit Relyence FMEA Software to learn more.