Reliability Prediction Analysis

Relyence

Nothing to download or install

Instant access, free web based trial

Reliability Modelling Made Simple

Relyence Reliability Prediction Software

Accelerate your MTBF calculations and component modelling with intuitive, browser-based reliability prediction software built for today’s engineering teams. Move beyond spreadsheets with our integrated approach, powerful libraries, and dashboards for complete confidence in results.

Relyence Reliability Prediction software enables engineers to perform accurate failure rate calculations and MTBF predictions without the limitations of manual spreadsheets. Supporting trusted standards such as MIL-HDBK-217 and Telcordia SR-332, it combines built-in component libraries, stress-driven calculations, and environmental profiles in one integrated platform. Designed to help you evaluate system reliability from early concept through to product lifecycle, Relyence makes it easy to analyse, share, and report. From aerospace to automotive, our web-based platform ensures your teams can collaborate on a single source of truth.

What our customers say...

This software is an absolute game changer and has significantly improved the way we connect to Reliability software companies: user-friendly interface, sales and support team, and comprehensive functionality. - Francisco O, Treetech Tecnologia

Predict reliability with speed, accuracy, and confidence — all in your browser.

Relyence Reliability Prediction software streamlines the process of modelling, analysing, and improving system reliability. By combining powerful standards-based calculation methods with a simple, intuitive interface, it empowers your engineers to build models quickly using component libraries, parts stress analysis, and environmental conditions. Whether you are performing early-stage MTBF predictions or refining designs with stress data, Relyence keeps your analyses clear, consistent, and connected. With dashboards, reports, and optional integrations across the Relyence suite, it provides the visibility and traceability needed for today’s reliability-driven industries.

Relyence Reliability Prediction key features

In addition to platform-wide capabilities, each Relyence module offers unique features developed for its specific analysis method. These specialist tools ensure engineers have the right functionality at the right time, helping achieve reliable, audit-ready results with less effort.

Relyence Reliability Prediction offers users the following benefits...

Integrated Reliability Prediction Models

Flexible Calculation Model Selection

Relyence Reliability Prediction gives you the freedom to work with multiple standards, including MIL-HDBK-217, Telcordia, and Siemens SN29500. Use one or more models in a single licence, and adjust them at subsystem or part level to suit your analysis.

Intelligent Part Mapping™

Simplify and accelerate your part library imports and data entry with Intelligent Part Mapping™. This feature automatically interprets your part descriptions text during data entry or when importing, identifying and assigning key attributes such as part category, subcategory, and type. For example, entering “Cap Ceramic 10uF 50V” in your .xlsx spreadsheet allows Relyence to map it directly to a capacitor component in the Reliability Prediction module whilst populating the additional part data.

Intelligent Part Mapping reduces manual data prep, ensures consistency with reliability prediction standards like MIL-HDBK-217, and gets you up and running faster—ideal when onboarding supplier BOMs or legacy datasets.

Knowledge Banks

Control Your FMEAs with Relyence Knowledge Banks

Relyence Knowledge Banks streamline your FMEA process by providing a centralised repository for all your approved FMEA data, failure modes, effects, causes, and corrective actions. Engineers can search this data to quickly access proven solutions, saving time and ensuring consistency across projects.

The push feature allows you to effortlessly update your analyses with the latest information, keeping your analyses aligned and compliant. Plus, with built-in usage tracking, you gain visibility into how often and where your Knowledge Banks data is being applied, helping to identify best practices and areas for improvement. It’s a smarter, more efficient way to drive your risk analysis.

Relyence Reliability Prediction Core Features

As part of the fully integrated Relyence platform, the Reliability Prediction module benefits from a wide range of shared features. These cross-module capabilities allow engineers to save time, avoid duplication, and ensure analyses remain accurate and consistent across projects. Many of the features most valued by our customers are built-in here — visit the features section for the full breakdown.

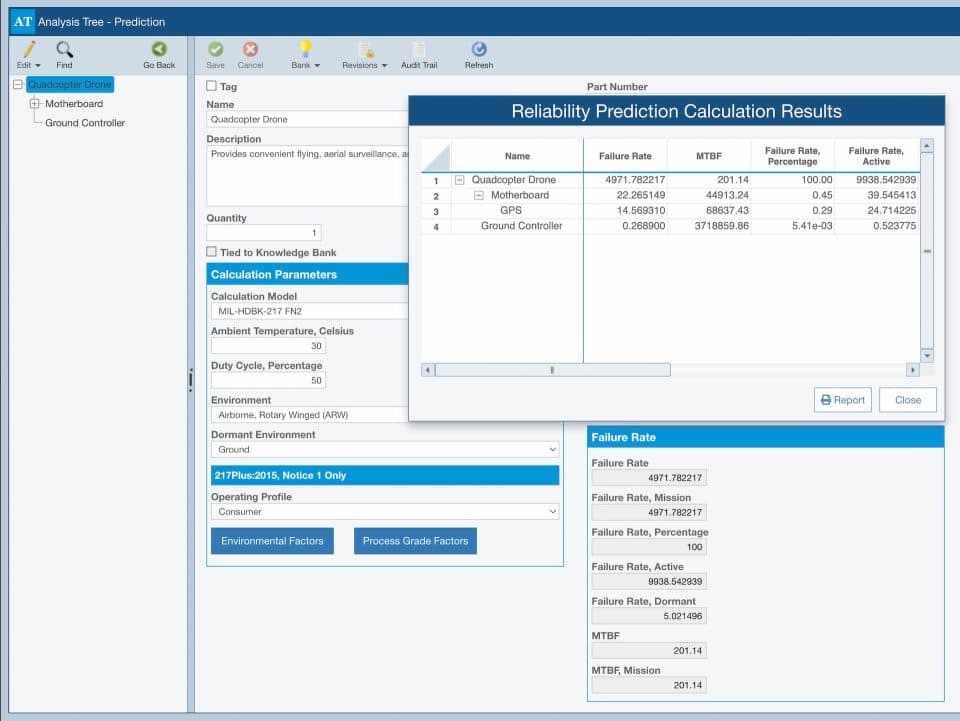

Analysis Tree

The Analysis Tree, positioned between the Relyence Sidebar and main analysis area, provides a clear, hierarchical breakdown of your system, product, or process. While optional, it’s highly recommended for organising your analysis effectively.

As you select items in the Analysis Tree, the data displays the relevant filtered information, keeping your focus on the specific subsystem or section you’re working on. This intuitive filtering helps streamline data management across your Relyence modules, including FMEA, FRACAS, Reliability Prediction, RCM, and Maintainability Prediction.

Audit Trail

Relyence’s Audit Trail feature tracks all modifications to your data, including additions, edits, and deletions, along with who made the changes and when.

In the example shown, the Audit Trail for a Design FMEA shows detailed records of changes made to failure cause data—listing each update, who made it, previous values, and timestamps in descending order. For a comprehensive view, you can also export a full Audit Report, filtering by date and module for concise tracking.

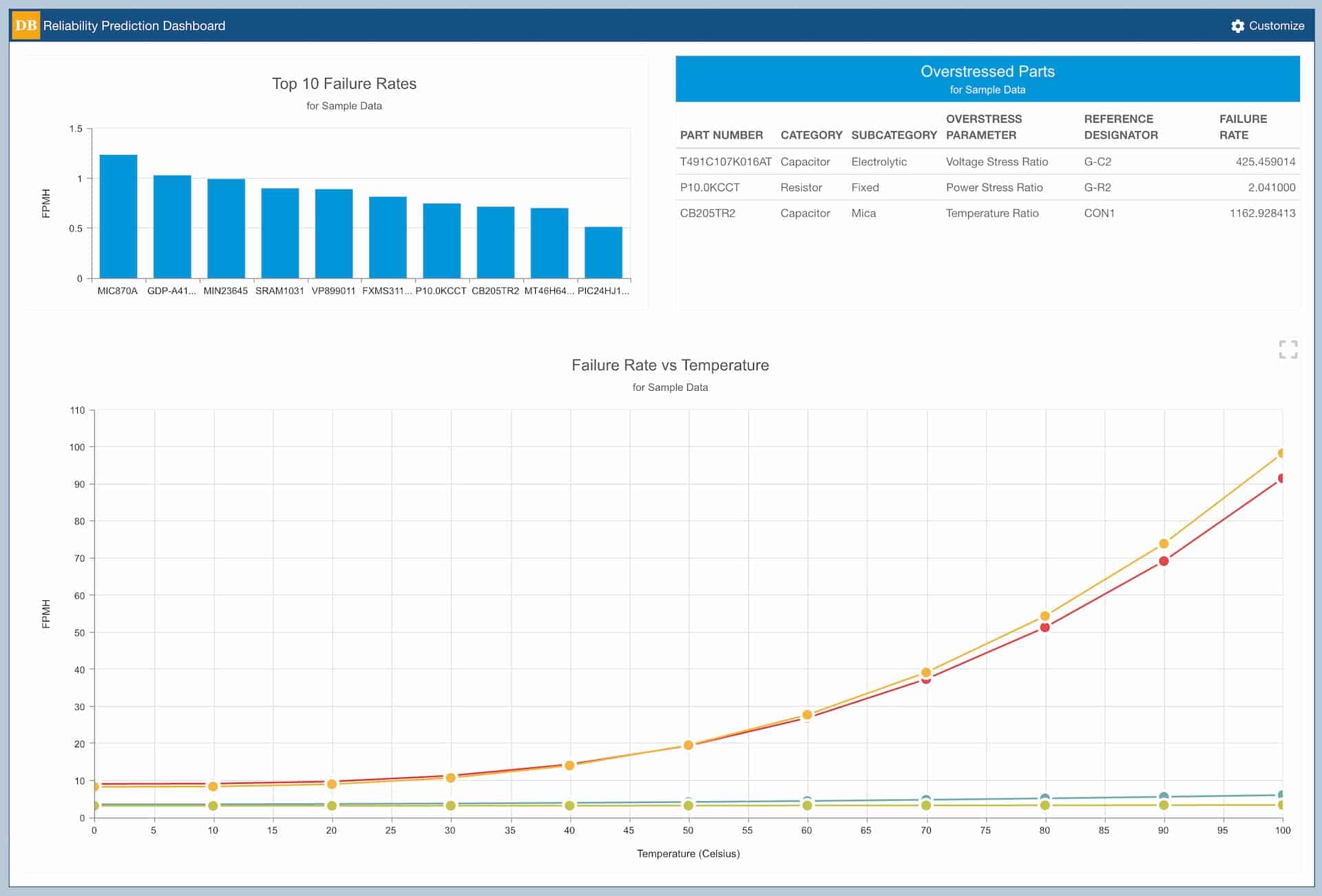

Customisable Dashboards & Drill‑down Reporting

Relyence Dashboards provide a comprehensive, customisable overview of your product or system by gathering and organising key data. Users can create unlimited, personalised Dashboards based on set permissions.Using the Dashboard Editor, add widgets such as charts, tables, and graphs for high-level visual insights—many with drill-down features that lead directly to detailed analysis files, highlighting specific data for in-depth review.

Our Reliability Prediction module shares data with the following Relyence products

Relyence Reliability Prediction Integrations

FMEA

Relyence FMEA software streamlines DFMEA, PFMEA, FMEA-MSR, and FMECA processes with intelligent features that save time and enhance consistency. With always-in-sync links to Control Plans and Process Flow Diagrams, Knowledge Banks for reuse, and built-in collaboration tools, it keeps your analyses accurate, compliant, and connected. Fully web-based, it’s the smarter way to manage FMEAs across teams and projects.

FRACAS

Relyence FRACAS software accelerates your reliability process with no-code customisations, allowing you to tailor failure reporting and corrective actions without IT support. It stands out by supporting industry standards such as 8D, DMAIC, and PDCA, as well as your own templates, and seamlessly connects with FMEA, Prediction, and Weibull tools to provide a single, unified reliability workflow.

RBD

Relyence RBD software turns Reliability Block Diagrams into a powerful decision-making tool. With an intuitive editor, reusable block libraries, and clear reporting, it simplifies complex modelling while enabling collaboration across teams. Integrated with Reliability Prediction and Weibull, it provides consistent insights from design through to service. A modern, browser-based tool for engineers in every sector.

DFMEA

Relyence DFMEA streamlines and improves design risk analysis, providing structure, speed, and consistency. Fully web-based, it helps teams move beyond spreadsheets with built-in workflows and approvals, keeping your projects on track. Knowledge Banks promote the reuse of proven functions, failure modes, effects, causes, and recommended actions, whilst SmartSuggest provides intelligent recommendations, enabling quicker and easier creation and maintenance of high-quality analyses.

FMECA

Relyence FMECA software combines MIL-STD-1629A rigour with modern collaboration tools. It helps engineers identify potential failures, assess criticality, and prioritise corrective actions where they matter most. With dashboards, audit trails, and seamless integration across the Relyence suite, it brings clarity and efficiency to criticality-driven risk management.

FTA

Transform risk management with Relyence Fault Tree Analysis Software—your essential visual tool for reliability and safety. Build fault trees with a simple diagram editor, reuse events and trees through libraries, and migrate from Excel with ease. With built-in collaboration, reporting, and integrations to FMEA and FRACAS, Relyence FTA delivers a connected approach to managing reliability across your organisation.

Relyence Reliability Prediction Overview

Relyence Reliability Prediction software provides engineers with a complete environment for accurate MTBF prediction and component reliability calculations. Supporting leading industry standards, including MIL-HDBK-217, Telcordia SR-332, NSWC-11, 217Plus, and more, it brings confidence to your reliability assessments. Built-in component libraries reduce the time required to construct reliability predictions, while parts count and parts stress methods ensure flexibility in your analyses. Environmental profiles and stress-driven calculations allow you to account for real-world conditions, providing insights that go beyond static numbers.

With intuitive dashboards, reporting tools, and web-based access, Relyence makes collaboration simple — enabling global teams to work together on a unified platform. You can easily import existing data directly from Excel, ensuring a smooth transition without losing valuable historical records. Designed to integrate with complementary Relyence tools such as Reliability Block Diagrams, Weibull, FMEA, and FRACAS, it enables a seamless flow of reliability data across your organisation.

From aerospace to automotive, electronics to medical devices, Relyence Reliability Prediction provides the tools engineers need to meet today’s demanding industry expectations.

A selection of Relyence Reliability Prediction Analysis software customers

Relyence Reliability Prediction Methodology

Reliability prediction is a structured way of estimating how long components and systems will perform before failure. At its core, it involves applying proven standards — such as MIL-HDBK-217 and Telcordia SR-332 — to component data under specific operating stresses and environments. By modelling each part and applying failure rate equations, engineers can calculate measures such as Mean Time Between Failures (MTBF).

Relyence simplifies this process. Instead of manually entering data into spreadsheets, engineers can use built-in component libraries, apply environmental factors, and run stress-driven calculations directly within the software. The system automatically performs the maths, generating consistent results while reducing the risk of error. The parts count method is typically used early in design, when details are limited, while parts stress methods give more precision once actual operating conditions are known.

Dashboards and reports make the results clear to both technical and non-technical stakeholders, ensuring reliability is communicated effectively across teams.

Relyence Reliability Prediction... is it the right choice for you?

Next Steps

Register for our free, no obligation web based trial.

No credit/debit card required, nothing to download/install.

or book a Zoom/Teams demo to find out more.