Maintainability Prediction

Relyence

Nothing to download or install

Instant access, free web based trial

Plan for Maintainability

Relyence Maintainability Prediction Software

Relyence Maintainability Prediction software applies the MIL-HDBK-472 methodology to model repair tasks, resources, and downtime, delivering MTTR insights and supportability metrics that engineers and managers can trust.

Effective maintenance planning forms the backbone of reliable system performance. Relyence Maintainability Prediction software provides a structured, web-based solution built on the proven methodology of MIL-HDBK-472. By modelling tasks, resources, and repair sequences, it delivers accurate Mean Time To Repair (MTTR) estimates and maintainability metrics. Engineers can share results through dashboards and reports that speak to both technical and management audiences. Integrated with Reliability Prediction, FRACAS, and RBD. Relyence Maintainability Prediction ensures maintainability is considered from the start — improving supportability and reducing costly downtime.

What our customers say...

“By applying MIL-HDBK-472 through Relyence, we were able to standardise our analyses, improve MTTR predictions, and communicate the results clearly across our teams.”

MIL-HDBK-472 based MTTR predictions you can rely on for supportability planning.

Maintainability is about designing systems that can be restored to service quickly, using the right people and tools. Relyence Maintainability Prediction software is based on MIL-HDBK-472, enables engineers to model repair tasks and forecast MTTR with precision. Intuitive dashboards and detailed reporting present results in decision-ready formats, helping you demonstrate maintainability in design reviews and trade-off studies. Web-based and collaboration-ready, Relyence Maintainability Prediction is trusted in aerospace, automotive, electronics, rail, and medical device sectors to reduce downtime and support informed supportability planning.

Relyence Maintainability key features

In addition to platform-wide capabilities, each Relyence module offers unique features developed for its specific analysis method. These specialist tools ensure engineers have the right functionality at the right time, helping achieve reliable, audit-ready results with less effort.

Relyence Maintainability offers users the following benefits...

Relyence Maintainability Core Features

As part of the fully integrated Relyence platform, the Maintainability module benefits from a wide range of shared features. These cross-module capabilities allow engineers to save time, avoid duplication, and ensure analyses remain accurate and consistent across projects. Many of the features most valued by our customers are built-in here — visit the features section for the full breakdown.

Our Maintainability module shares data with the following Relyence products

Relyence Maintainability Integrations

Relyence Maintainability Overview

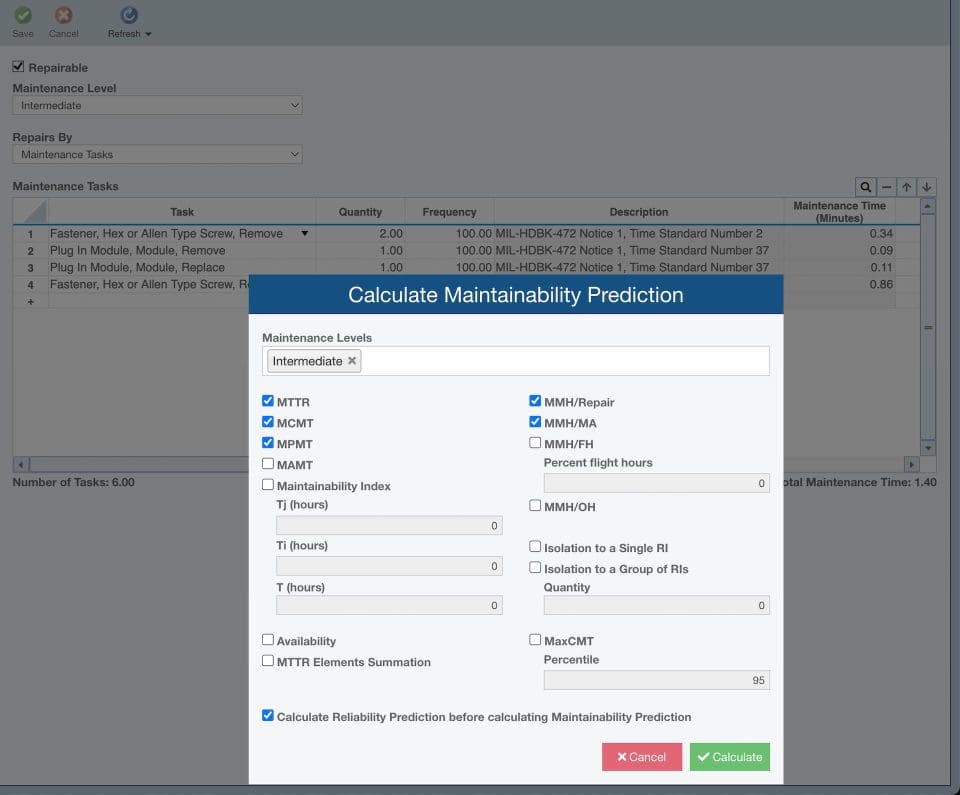

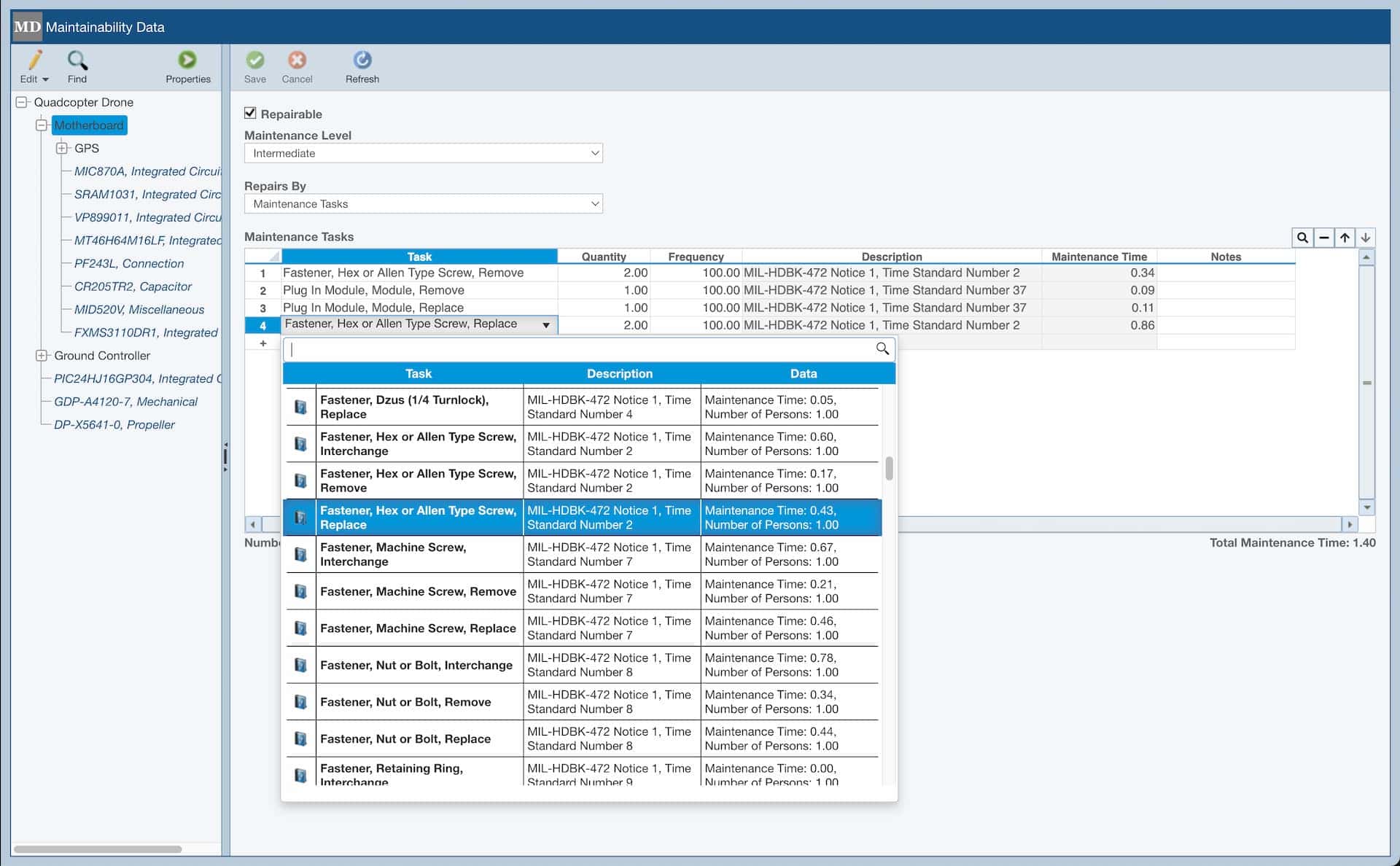

Relyence Maintainability Prediction software provides a structured, standards-based approach to supportability planning. Using the MIL-HDBK-472 methodology enables engineers to model repair actions, evaluate resource needs, and estimate Mean Time To Repair (MTTR) for systems and subsystems.

Task libraries simplify model building, while dashboards and reports translate technical results into clear outputs for decision-makers. With built-in governance features like audit trails, you can ensure analyses remain traceable and compliant.

The software integrates seamlessly with Relyence Reliability Prediction, ensuring maintainability predictions form part of a wider reliability and risk management strategy. For teams migrating from spreadsheets, import/export features streamline the transition, improving accuracy and consistency.

From aerospace and automotive to electronics, medical devices, and rail, Relyence Maintainability Prediction helps organisations apply MIL-HDBK-472 efficiently, anticipate downtime, and optimise maintenance strategies from the outset.

A selection of Relyence Maintainability Prediction software customers

Relyence Maintainability Methodology

Relyence Maintainability Prediction software is based on MIL-HDBK-472, the widely recognised standard for maintainability analysis. This methodology breaks down every maintenance task into steps, identifying the tools, skills, and resources required. By estimating the time taken for each step, engineers can calculate the Mean Time To Repair (MTTR) of a system or component.

The process goes beyond guesswork — it provides a structured, repeatable framework that ensures analyses are consistent and comparable across projects, providing teams with the data they need to make informed decisions about design and maintenance.

Relyence makes applying MIL-HDBK-472 straightforward. With digital libraries, templates, dashboards, and reporting tools, it replaces spreadsheets with a web-based environment that is collaborative, auditable, and scalable. This enables engineering teams to bring maintainability analysis into everyday design processes, reducing downtime risks and improving lifecycle performance.

More information on our Maintainability Prediction software…

Relyence Maintainability... is it the right choice for you?

Next Steps

Register for our free, no obligation web based trial.

No credit/debit card required, nothing to download/install.

or book a Zoom/Teams demo to find out more.